Benefits

› Versatile designs

› High quality construction

› Simplified installation with less onsite labor

Optimized pump systems for chilled & condenser water loops

Directly Interface with the Chiller built-in plant manager. Single point responsibility for Chiller + Controls + Pumps Backed up by Daikin Warranty and Service Network.

BENEFITS

1. Single electrical connection

2. Simplified installation, startup and commisioning.

3. Compact footprint

4. Integrated control & Instrumentation

5. Fully adaptable to your application

STANDARD DESIGN INCLUDES:

• Base mounted, end suction pumps

• Daikin Intelligent Pump Manager Controller

• Suction Diffusers

• Triple duty valves

• Manual Gauges

• Pump common discharge header

• Pump common suction header

• Lifting lugs

TECHNICAL DATA

All Daikin skids are assembled on a steel base with or without enclosure. They arrive on site pre-wired, pre-piped and pre-commissioned, eliminating the scheduling challenges and cost overruns of a site-built system.

| System Conditions | Range |

| System head (bars) | 3 to 6 |

| System flow rate (Ips) | up to 380 |

| Number of pumps | 2 to 5 |

| Motor power (kW) | 10 to 200 |

| Optional Components |

| Vertical inline or split case pumps |

| Variable frequency drives (VFD) |

| Power distribution |

| Intelligent Pump Manager & instrumentation |

| Air separator |

| Pressurization Unit |

| Expansion tank |

| Suction diffusers |

| Check valves |

| Chemical pot feeder |

| Glycol feeder |

| Buffer tank |

| Plate Heat Exchanger |

| Inertia Base |

| Insulation |

| Cladding |

Standard Pump Skid

Pump skid with / Optional components options

SKID DIMENSIONS

*Dimensions shown for standard skid systems

| Header Size (mm) | L (m) | W (m) | H (m) |

| 150 | 2.1 | 2.6 | 2.3 |

| 200 | 2.1 | 2.6 | 2.3 |

| 250 | 2.5 | 2.7 | 2.5 |

| 300 | 2.5 | 3.3 | 2.5 |

2-Pump Systems

| Header Size (mm) | L (m) | W (m) | H (m) |

| 200 | 3 | 2.6 | 2.3 |

| 250 | 3.5 | 2.6 | 2.3 |

| 300 | 3.7 | 2.7 | 2.5 |

| 350 | 3.7 | 2.7 | 2.5 |

| 400 | 3.7 | 3.3 | 2.5 |

3-Pump Systems

| Header Size (mm) | L (m) | W (m) | H (m) |

| 250 | 4 | 2.6 | 2.3 |

| 300 | 4.5 | 2.6 | 2.3 |

| 350 | 4.5 | 2.6 | 2.3 |

| 400 | 4.9 | 2.7 | 2.5 |

| 450 | 4.9 | 3.3 | 2.5 |

4-Pump Systems

Types

Energy transfer station skids

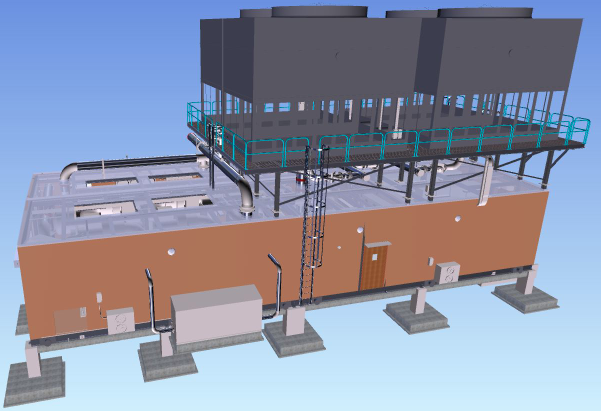

Air-cooled Chiller Skid

Pumping skids

Custom Process Cooling/Heating Skid

Learn More

-

Pre Fabricated Modular Solution

Pre - fabricated modular solutions provide much needed flexibility for various construction projects of the public and private sector. -

Containerized Solutions

-

Modular Chiller Plant

Your alternative to site built plants

Related Documents

-

Pre-Fabricated Modular Solutions Leaflet_HRPDF | 7.74MB

Pre-Fabricated Modular Solutions Leaflet_HRPDF | 7.74MB -

Packaged Plant Solutions Leaflet_v4PDF | 7.61MB

Packaged Plant Solutions Leaflet_v4PDF | 7.61MB -

Pump Skid Flyer CataloguePDF | 4.28MB

Pump Skid Flyer CataloguePDF | 4.28MB

FIND MY PRODUCT

DISCOVER OUR PRODUCTS

Find the perfect match for your unique needs and preferences in the Daikin product portfolio.

SALES NETWORK

NEARBY DAIKIN DEALERS

Use the Dealer Locator to easily connect with trusted Daikin experts near you.

NEED HELP?

ENQUIRIES AND SUPPORT

Our team is here to help for any of your questions. Get in touch!